[ad_1]

Fabrication of hydrogel-plastic hybrids

Primarily based on the bonding mechanism of adductor-muscle, we constructed a riveting layer with the flexibility to bind with each substrate and gel networks. Determine S1 reveals the chemical grafting means of the riveting layer. First, the floor of the plastic was activated by the directional plasma, and reactive hydroxyl teams had been shaped after the hydrogen peroxide therapy. Then, the carbon‒carbon double bonds that may very well be copolymerized with the monomers had been riveted on the floor by utilizing acryloyl chloride (AC). Subsequently, in situ free radical-initiated polymerization was used to make sure polymer chain propagation ranging from the riveting level. As proven in Fig. 1b, such epitaxially grown hydrogel networks from the substrate shaped secure chemical cross-links, which might overcome the weak interfacial bonding originating from the floor instability of the hydrogel. To confirm the mechanisms of in situ free radical-initiated polymerization epitaxially grown, Fourier rework infrared spectroscopy (FTIR) was carried out to research the modifications within the chemical composition and microstructure of the substrate floor. As Fig. S2 reveals, the height related to the C = C bond at 1640 cm−1 was intensified after acryloyl chloride modification and weakened after UV-initiated polymerization. This statement indicated the anchoring and consumption processes20,21. Moreover, we carried out XPS measurements on PVC samples that had been polymerized utilizing DMAPS and 2-hydroxyethyl methacrylate phosphate (HEMAP) precursor options. In Fig. 1c, the PVC pattern polymerized with DMAPS precursor resolution exhibited two peaks within the S 2p area at roughly 167 eV and 168 eV. These peaks corresponded to the attribute vitality ranges of the covalently bonded sulfonic acid group22. Moreover, the PVC pattern polymerized with HEMAP precursor resolution confirmed a further peak within the P 2p area (Fig. 1d). This statement confirmed the profitable grafting of DMAPS and HEMAP polymer brushes onto the PVC substrate. The development of the riveting polymer brush (polyacrylamide) on the PVC substrate was confirmed by the AFM pictures (Fig. S3). This dense nanostructure indicated the excessive density of riveting websites, in addition to the environment friendly interfacial radical switch response between the riveting website and hydrogel monomers.

Sturdy bonding between the delicate hydrogels and strong plastics

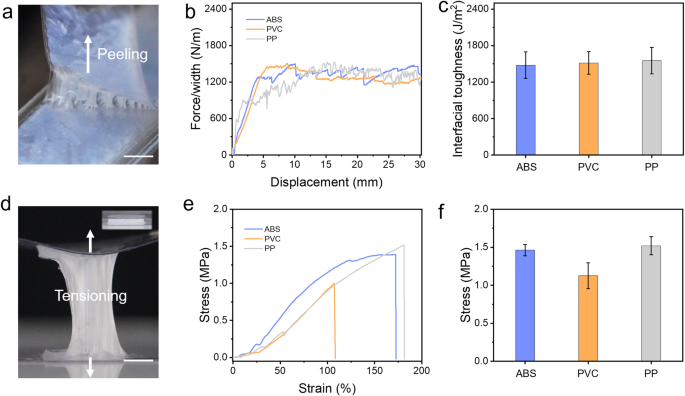

The bonding energy between delicate hydrogels and strong plastic substrates is among the key components in evaluating the steadiness and reliability of hydrogel-plastic hybrids23,24,25,26. Right here, peeling measurements had been carried out to calculate the interfacial toughness. Typically, the interactive pressure between the hydrogel and the plastic with low floor vitality was weak. As proven in Fig. S4 and Supplementary Film S1, the hydrogel constructed on the untreated plastic substrate simply indifferent within the peeling course of, exhibiting virtually no interfacial fracture toughness towards the exterior pressure. Determine 2a reveals the peeling means of hydrogel-plastic hybrids; a big deformation of the hydrogel in each the interface and bulk was noticed. Theoretically, the interfacial cracks might kink and propagate within the hydrogel community, which was comparatively brittle, dissipating mechanical vitality (ΓD). Subsequently, the interface energy examined by the peeling measurement was the sum of the intrinsic work of bonding (Γ0) and the dissipated mechanical vitality of the hydrogel (ΓD), which may very well be expressed as Γ = ΓD + Γ0 (1)27. To keep away from gel fragmentation within the peeling course of, a poly(DMAPS-co-AA) hydrogel with excessive ductility was chosen. Determine 2b reveals the calculated peeling forces per width of the hydrogel-plastic hybrids. All peeling curves exhibited the identical development; a rise within the peeling pressure produced fast progress, adopted by a flattening of the curves at a excessive degree. Moreover, the peeling forces between the hybrids primarily based on completely different plastics, similar to PP, PVC and ABS, had been virtually the identical, which demonstrated the nice generality of our technique. Furthermore, this similarity indicated that the bonding energy between the hydrogel and the plastics was greater than the fracture energy of the hydrogel. When the peeling pressure reached the fracture worth of the hydrogel community, the crack started to propagate alongside the majority hydrogel close to the bonding interface. As proven in Fig. 2c, the typical interfacial toughnesses of the hydrogel-plastic hybrids had been throughout 1450 J m−2.

a Optical pictures of the peeling course of; the dimensions bar is 0.5 cm. b Curves of the peeling pressure per width versus displacement for the assorted varieties of hydrogel-plastic hybrids. c Measured interfacial toughness values of the hybrids. d Digital image of the tensioning course of; the dimensions bar is 0.5 cm. The inset reveals its authentic state. e Tensile stress of the hybrids primarily based on ABS, PVC and PP. f Statistical tensile stress of the hybrids.

As proven in Fig. 2d, tensile exams had been carried out to offer additional perception into the bonding energy of the hybrids. On this experiment, the ductility of the hydrogel didn’t have a right away impact on the outcomes, such because the peeling measurement. Subsequently, the PVA/AAm double-network hydrogel with excessive energy and modulus (Fig. S5) was helpful for predicting the true interfacial toughness. Determine 2e reveals the stress‒pressure curves of the hybrids with PP, PVC and ABS substrates. The tensile pressure on the bonding interface per unit space quickly elevated with the tensile pressure, and its sudden fracture occurred when the pressure reached a particular worth. As proven in Fig. S6, the samples constructed utilizing the hydrogels with excessive energy represented the interfacial fracture. In distinction, the samples ready by hydrogels with weak mechanical energy exhibited fracture on the hydrogel community after separation. These outcomes indicated that the precise bonding strengths of the hydrogel-plastic hybrids may very well be obtained with these measurements. As proven in Fig. 2f, the PP-based and ABS-based hybrids have comparable common interfacial strengths, which had been 1.52 and 1.46 MPa, respectively. Nevertheless, the interfacial energy of the hybrids primarily based on PVC was 1.13 MPa, which was close to 75% of the others. This may very well be brought on by the completely different polymer chains of the plastics, which had been associated to the formation of radicals on the substrate floor underneath plasma therapy28 and led to the distinct density of the riveting websites.

With the event and promotion of robots with varied scales, the macroscopic integration of sentimental and inflexible supplies can’t handle all the required situations. For instance, hydrogels with biomimetic micro/nanostructures may very well be used for environmental sign detection and movement monitoring, and micron-scale gel-based ionic circuits may very well be utilized in bioionic sign transmission. Thus, we additional evaluated the interfacial bonding behaviors of micron-scale hydrogels on the plastic substrates. As proven in Fig. S7, a micron-scale trapezoid with a prime width of 70 μm, a backside width of 90 μm and a top of 25 μm was efficiently constructed on the plastic substrates. Furthermore, three trapezoidal hydrogels had been organized within the subject of view based on the design, and all constructions remained intact after demolding resulting from interfacial bonding. This would offer a brand new idea and preparation resolution for the design and utility of gel-based microcircuits.

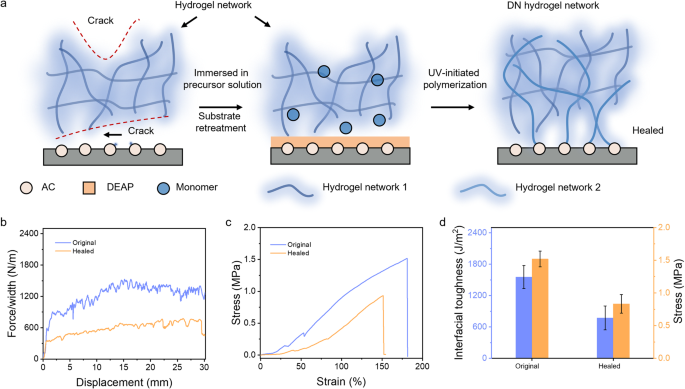

Though the delicate and weak hydrogel parts may very well be protected by inflexible plastic, there’ll nonetheless be a big distinction within the diploma of attrition between them in sensible purposes. Half substitute is an efficient method to resolve the issue. As proven in Fig. 3a, the hydrogel community, in addition to the bonding interface, may very well be broken, ensuing within the practical failure of the hydrogel-plastic hybrids. At this second, the plastic substrates may very well be recycled by secondary therapy, reforming the lively riveting websites. The broken hydrogel can be immersed within the precursor resolution to swell the monomers after which positioned on the floor of the substrates (emptying the air bubbles within the interface between hydrogel and plastic). Lastly, the crack may very well be healed by forming the second hydrogel community after UV-initiated polymerization. Determine S8 reveals the therapeutic means of the hydrogel-plastic hybrids. The interfacial bonding energy of the hybrids was additionally evaluated by peeling and tensile exams. As proven in Fig. 3b, the peeling forces per width of the PP-based pattern reached 796 J m−2. The peeling curves exhibited the identical development because the origin, which demonstrated the binding interplay between the gel and the substrate. The stress‒pressure curve additionally demonstrated profitable interfacial bonding, exhibiting a tensile stress of 0.83 MPa (Fig. 3c). Notably, the bonding energy between hydrogels and secondary therapy substrates was comparatively decrease than the unique energy, despite the fact that the mechanical energy of the delicate community was improved by establishing a double community (DN) hydrogel. This consequence originated from the decrease density of lively riveting websites. In the identical method, prefabricated hydrogels with particular sizes and styles may be bonded on plastic to kind practical hybrids, which might facilitate extra comfort to their design and utility.

Purposes of the hydrogel-plastic hybrids originating from robust bonding

The potential purposes of our hydrogel-plastic hybrids are proven in Fig. 4. First, the relative place of the hydrogel and substrate was fastened; thus, the hydrogel may very well be positioned within the “armor” constructed by the plastic. In the same method that the arduous shell of the mussel protects the hydrogel-like muscle tissues, the hydrogel core of the hybrid could be protected towards exterior forces, similar to scratching and knocking (Fig. 4a). As proven Fig. 4b, the sturdy bonding between the hydrogel and the plastic makes it doable for the hybrids to imitate joint actions, together with stretching, bending and twisting. These hybrids compensate for the restrictions of the small movement vary of the plastic and the overly straightforward deformation of sentimental hydrogels and will present the premise for synthetic robots to breed the operate of bones and delicate connective tissues (tendon, ligament, and so on.). Moreover, a form reminiscence hydrogel (poly(AAm-co-PEA)) with temperature responsiveness was used to assemble the hydrogel-plastic hybrids19. As Fig. 4c reveals, the temperature-responsive gel acts just like the adductor muscle that shops and releases vitality when it’s underneath exterior assault (excessive temperature). By warming the encompassing setting above the temperature of the part transition (Tm, 37 °C), the elongated “synthetic muscle” releases the saved vitality and recovers its authentic form. In consequence, the plastic shell closes underneath the driving pressure transmitted by the bonding. Notably, the flexibility of hybrids to modify between open and closed states repeatedly depends on the responsiveness and cyclic mechanical properties of the hydrogel itself. As demonstrated within the cyclic tensile check (20% pressure) (Fig. S9), the stress ranges stay in the identical order as the unique even after 50 cycles, indicating that the hydrogel-plastic hybrid reveals glorious cyclic sturdiness. These outcomes display that our hydrogel-plastic hybrids present a brand new kind of practical materials for clever robots.

a Scratch resistance of the hybrids, exhibiting the safety of the hydrogel-based core that may be a just like the safety supplied by a mussel; the dimensions bar is 0.5 cm. b Hydrogel bonding as a versatile junction, which may mimic the joint actions of organisms; the dimensions bar is 0.5 cm. c Closure of the unreal plastic shell underneath the driving pressure transmitted by the bonding hydrogel muscle with temperature responsiveness; the dimensions bar is 1 cm.

[ad_2]