[ad_1]

Researchers at Princeton have developed an extraction method that slashes the quantity of land and time wanted for the manufacturing of lithium, a important part of the batteries on the coronary heart of electrical autos and vitality storage for the grid. The researchers say their system can enhance manufacturing at current lithium services and unlock sources beforehand seen as too small or diluted to be worthwhile.

Lithium is vital to the a clear vitality future. However producing the silvery-white steel comes with important environmental prices. Amongst them is the huge quantity of land and time wanted to extract lithium from briny water, with giant operations working into the handfuls of sq. miles and sometimes requiring over a 12 months to start manufacturing.

The core of the brand new extraction method, featured on the cowl of this month’s difficulty of Nature Water, is a set of porous fibers twisted into strings, which the researchers engineered to have a water-loving core and a water-repelling floor. When the ends are dipped in a salt-water answer, the water travels up the strings by means of capillary motion — the identical course of bushes use to attract water from roots to leaves.

The water shortly evaporates from every string’s floor, forsaking salt ions equivalent to sodium and lithium. As water continues to evaporate, the salts grow to be more and more concentrated and finally type sodium chloride (desk salt) and lithium chloride crystals on the strings, permitting for straightforward harvesting.

Along with concentrating the salts, the method causes lithium and sodium to crystallize at distinct places alongside the string because of their totally different bodily properties. Sodium, with low solubility, crystallizes on the decrease a part of the string, whereas the extremely soluble lithium salts crystallize close to the highest. The pure separation allowed the crew to gather lithium and sodium individually, a feat that in any other case requires the usage of extra chemical compounds.

“We aimed to leverage the elemental processes of evaporation and capillary motion to pay attention, separate, and harvest lithium,” stated Z. Jason Ren, professor of civil and environmental engineering and the Andlinger Middle for Power and the Atmosphere at Princeton and the chief of the analysis crew. “We don’t want to use extra chemical compounds, as is the case with many different extraction applied sciences, and the method saves lots of water in comparison with conventional evaporation approaches.”

Restricted provide of lithium is one impediment to the transition to a low-carbon society, Ren added. “Our strategy is reasonable, straightforward to function, and requires little or no vitality. It’s an environmentally pleasant answer to a crucial vitality problem.”

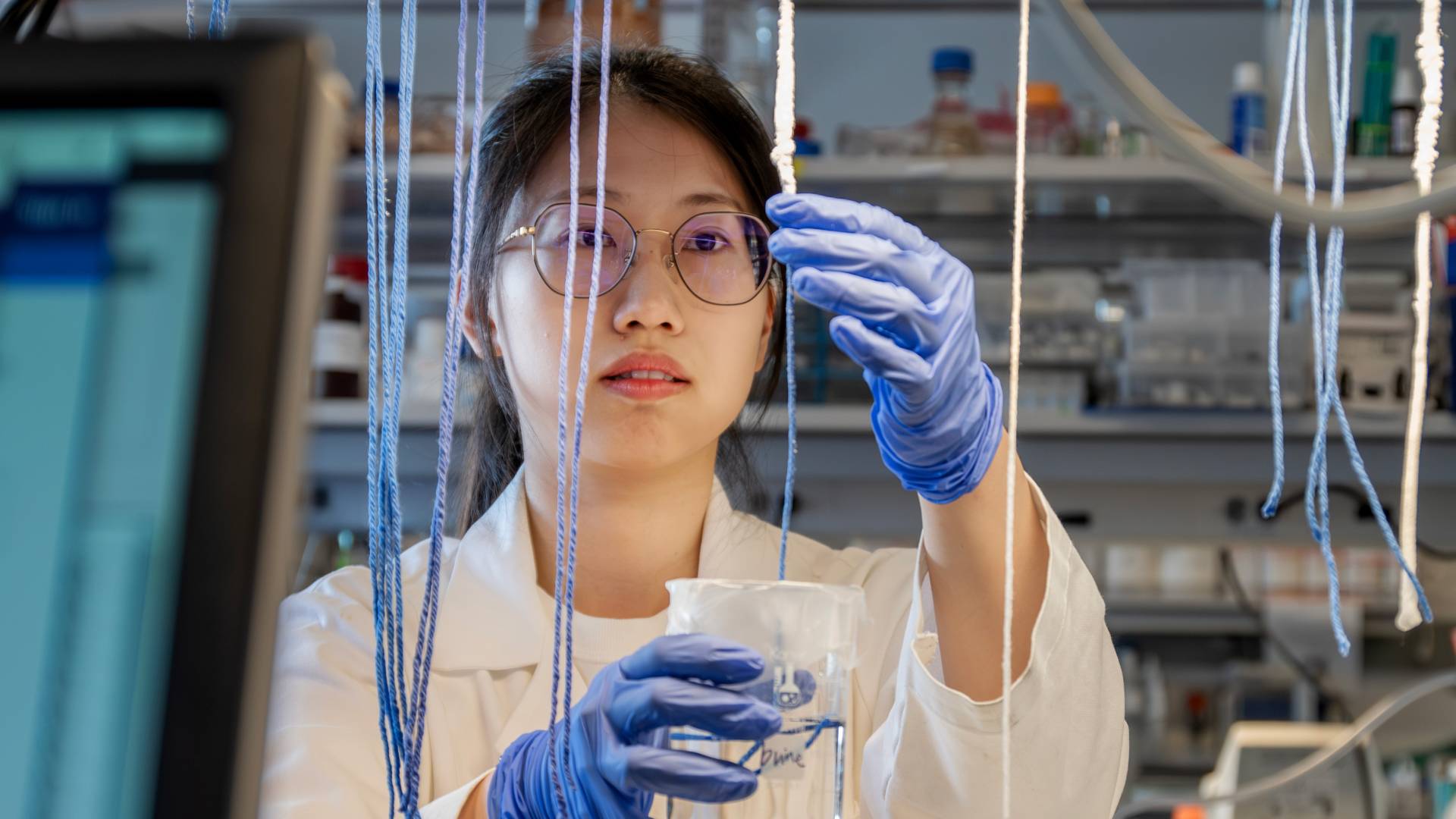

Meiqi Yang, a graduate pupil in civil and environmental engineering and one of many examine’s lead authors, operates the revolutionary strategy to lithium extraction.

An evaporation pond on a string

Standard brine extraction includes constructing a collection of big evaporation ponds to pay attention lithium from salt flats, salty lakes or groundwater aquifers. The method can take wherever from a number of months to some years. The operations are solely commercially viable in a handful of places world wide which have sufficiently excessive beginning lithium concentrations, an abundance of obtainable land and an arid local weather to maximise evaporation. As an example, there’s solely one lively brine-based lithium extraction operation in the USA, positioned in Nevada and overlaying greater than seven sq. miles.

The string method is much extra compact and may start producing lithium way more shortly. Though the researchers warning that it’s going to take extra work to scale their know-how from the lab to industrial scale, they estimate it may well lower the quantity of land wanted by greater than 90% of present operations and may speed up the evaporation course of by greater than 20 instances in comparison with conventional evaporation ponds, probably yielding preliminary lithium harvests in lower than one month.

Compact, low-cost and fast operations may broaden entry to incorporate new sources of lithium, equivalent to disused oil and fuel wells and geothermal brines, which are presently too small or too dilute for lithium extraction. The researchers stated the accelerated evaporation charge may additionally enable for operation in additional humid climates. They’re even investigating whether or not the know-how would enable for lithium extraction from seawater.

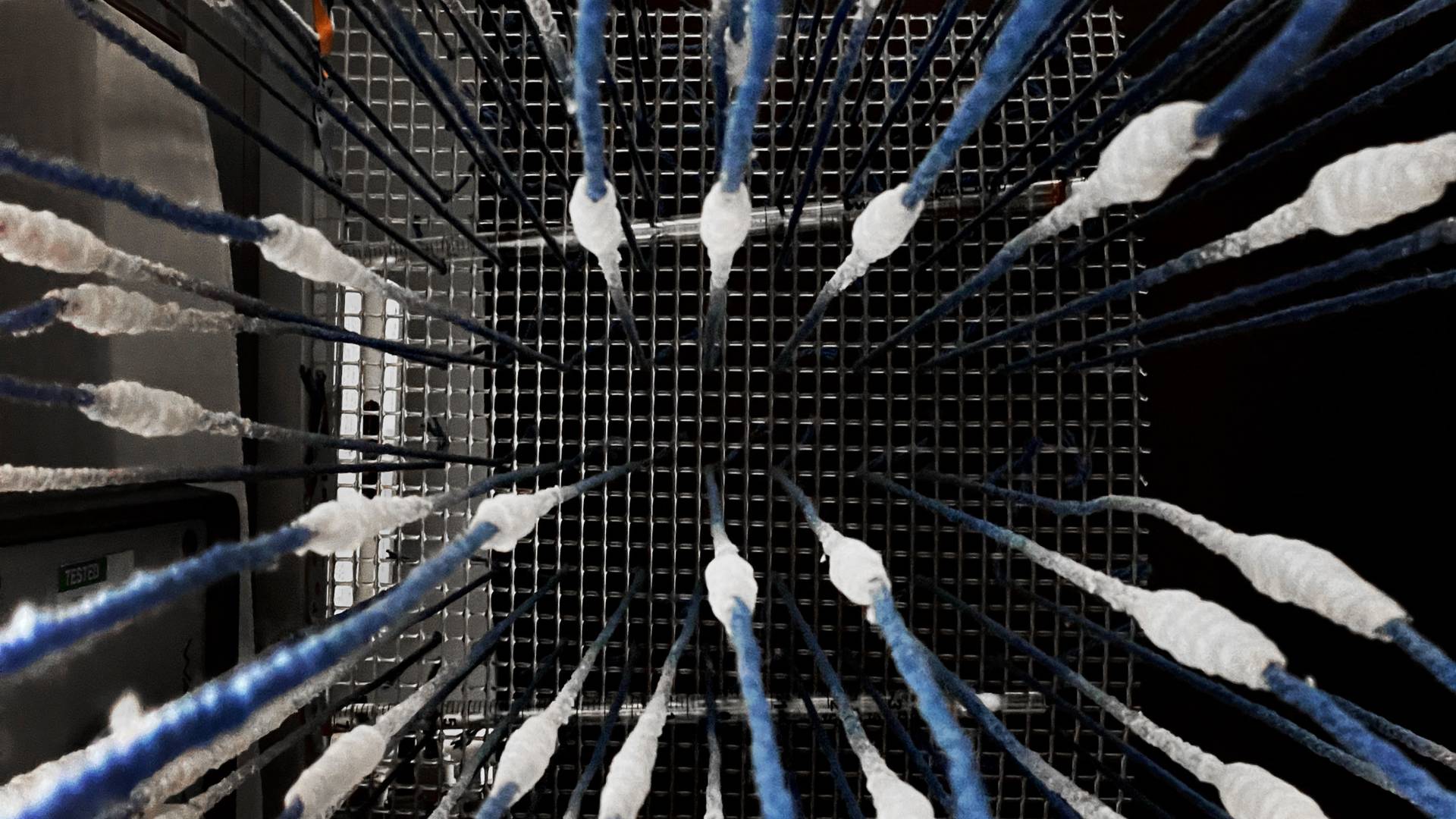

The researchers constructed an array of lithium-harvesting strings to show the scalability of their method.

“Our course of is like placing an evaporation pond on a string, permitting us to acquire lithium harvests with a considerably lowered spatial footprint and with extra exact management of the method,” stated Sunxiang (Sean) Zheng, examine co-author and former Andlinger Middle Distinguished Postdoctoral Fellow. “If scaled, we could open up new vistas for environmentally pleasant lithium extraction.”

Because the supplies to supply the strings are low-cost and the know-how doesn’t require chemical remedies to function, the researchers stated that with extra enhancements, their strategy can be a robust candidate for widespread adoption. Within the paper, the researchers demonstrated the potential scalability of their strategy by establishing an array of 100 lithium-extracting strings.

Ren’s crew is already creating a second technology of the method that can allow higher effectivity, greater throughput, and extra management over the crystallization course of. He credit the Princeton Catalysis Initiative for offering crucial preliminary assist to allow artistic analysis collaborations. Moreover, his crew lately acquired an NSF Partnerships for Innovation Award and an award from Princeton’s Mental Property (IP) Accelerator Fund to assist the analysis and growth course of, together with methods to change the strategy to extract different crucial minerals along with lithium. Along with Kelsey Hatzell, assistant professor of mechanical and aerospace engineering and the Andlinger Middle for Power and the Atmosphere, Ren additionally acquired seed funding from the Princeton Middle for Complicated Supplies to raised perceive the crystallization course of.

Zheng is main the launch of a startup, PureLi Inc., to start the method of refining the know-how and finally bringing it to the broader market. Zheng was chosen as one in every of 4 researchers within the inaugural START Entrepreneurs cohort at Princeton, an educational fellowship and startup accelerator designed to foster inclusive entrepreneurship.

“As a researcher, you understand firsthand that many new applied sciences are too costly or troublesome to scale,” Zheng stated. “However we’re very enthusiastic about this one, and with some extra effectivity enhancements, we expect it has unimaginable potential to make an actual impression on the world.”

A string of collaborators

Ren stated the breakthrough discovery was made doable by means of an in depth collaborative effort between analysis teams at Princeton and the College of Maryland.

For instance, working with Liangbing Hu, the Herbert Rabin Distinguished Professor within the Division of Mechanical Engineering on the College of Maryland, impressed the researchers to make use of and deal with the fiber materials to maximise the know-how’s effectivity.

Ren’s analysis crew additionally turned to Howard Stone, the Donald R. Dixon ’69 and Elizabeth W. Dixon Professor of Mechanical and Aerospace Engineering, and Fernando Temprano-Coleto, an Andlinger Middle Distinguished Postdoctoral Fellow working with Stone, to know and mannequin the elemental fluid mechanics and transport processes that underpin the strings’ spectacular lithium-harvesting capabilities.

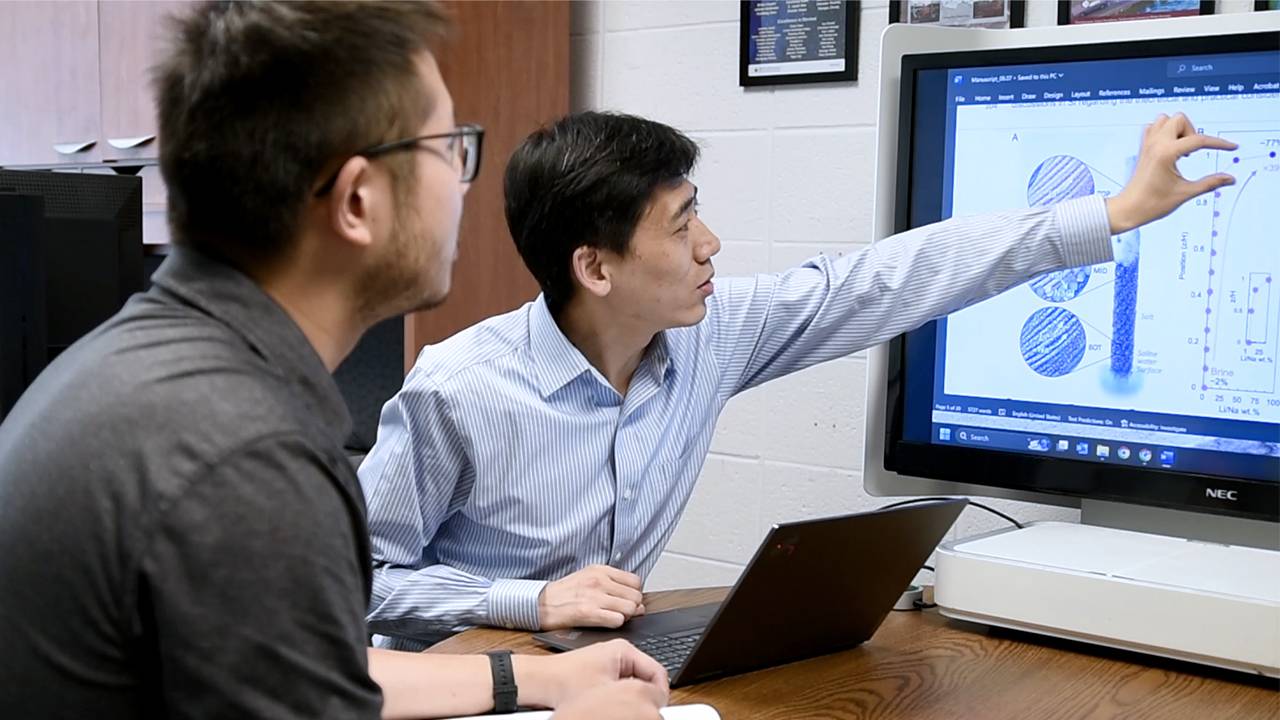

From left: Sunxiang (Sean) Zheng and Z. Jason Ren assessment knowledge exhibiting that lithium crystallizes close to the highest of every string.

“As soon as you possibly can arrive at a mathematical description of the method, not solely are you able to perceive what you’ve already noticed, however you additionally acquire predictive energy,” stated Temprano-Coleto. “With a mannequin in place, you can begin to play with the variables to optimize the method and perceive the way it will carry out beneath totally different situations.”

Ren’s crew tapped into the supplies characterization experience of Nan Yao, professor of the observe on the Princeton Supplies Institute, and the distinctive services obtainable at Princeton’s Imaging and Evaluation Middle to characterize the supplies’ construction and spatial association. Yao is the middle’s director.

“It’s troublesome to detect a component like lithium utilizing conventional characterization methods as a result of it’s so mild, with solely three electrons concerned to emit a really weak X-ray sign,” stated Yao. “Thankfully, on the Imaging and Evaluation Middle, we’ve a set of high-end, cutting-edge instrumentation that enabled us to gather the data we would have liked.”

Yao and Guangming Cheng, an affiliate analysis scholar in Yao’s group, labored with lead writer Xi Chen, a former affiliate analysis scholar in Ren’s lab who’s now an affiliate professor at Tsinghua College, to make use of a sophisticated method referred to as electron vitality loss spectroscopy alongside scanning transmission electron microscopy to characterize the spatial association of lithium and sodium alongside the strings. Their work revealed that lithium and sodium separated from one another vertically alongside the string in addition to radially, with sodium crystallizing totally on the floor of the interwoven strings and lithium concentrating within the heart. The invention may inform ongoing efforts to extend the effectivity of the present strategy.

“Every of our collaborators contributed a critically vital piece to our work, from uncovering the elemental processes behind the excessive effectivity of our know-how to characterizing the ultimate supplies,” Ren stated. “We couldn’t have completed our work with out the experience of everybody on the venture.”

“Spatially Separated Crystallization for Selective Lithium Extraction from Saline Water” was printed on-line Sept. 7 in Nature Water and featured on the duvet of the Sept. 18 print version. Along with Ren, Zheng, Hu, Temprano-Coleto, Stone, Yao, Cheng, and Chen, examine authors embody Meiqi Yang of Princeton College and Qi Dong of the College of Maryland. This analysis was supported by the Princeton Catalysis Initiative, Princeton’s Imaging and Evaluation Middle, the Andlinger Middle for Power and the Atmosphere, and the Nationwide Science Basis (NSF-MRSEC DMR-2011750).

[ad_2]