[ad_1]

A crew led by Virginia Tech researchers has developed a brand new methodology for upcycling plastics into high-value chemical substances often called surfactants, that are used to create cleaning soap, detergent, and extra. The work was printed in Science.

Plastics and soaps are likely to have little in widespread in the case of texture, look, and, most significantly, how they’re used. However there’s a shocking connection between the 2 on a molecular degree: The chemical construction of polyethylene—one of the generally used plastics on the earth at the moment—is strikingly just like that of a fatty acid, which is used as a chemical precursor to cleaning soap. Each supplies are product of lengthy carbon chains, however fatty acids have an additional group of atoms on the finish of the chain.

Guoliang “Greg” Liu, affiliate professor of chemistry within the Virginia Tech Faculty of Science, had lengthy felt this similarity implied that it must be attainable to transform polyethylene into fatty acids—and with a couple of further steps to the method—to supply cleaning soap. The problem was the best way to break an extended polyethylene chain into many quick—however not too quick—chains and the best way to do it effectively. Liu believed there was the potential for a brand new upcycling methodology that would take low-value plastic waste and switch it right into a high-value, helpful commodity.

Having thought of the query for a while, Liu was struck by inspiration whereas having fun with a winter night by a fire. He watched the smoke rise from the fireplace and considered how the smoke was made up of tiny particles produced in the course of the wooden’s combustion. Though plastics ought to by no means be burned in a fire for security and atmosphere causes, Liu started to surprise what would occur if polyethylene could possibly be burned in a protected laboratory setting.

Would the unfinished combustion of polyethylene produce “smoke” identical to burning wooden does? If somebody have been to seize that smoke, what would it not be product of?

“Firewood is generally product of polymers comparable to cellulose. The combustion of firewood breaks these polymers into quick chains, after which into small gaseous molecules earlier than full oxidation to carbon dioxide,” mentioned Liu, holder of the Blackwood Junior College Fellowship of Life Sciences within the Division of Chemistry. “If we equally break down the artificial polyethylene molecules however cease the method earlier than they break all the best way right down to small gaseous molecules, then we should always get hold of short-chain, polyethylene-like molecules.”

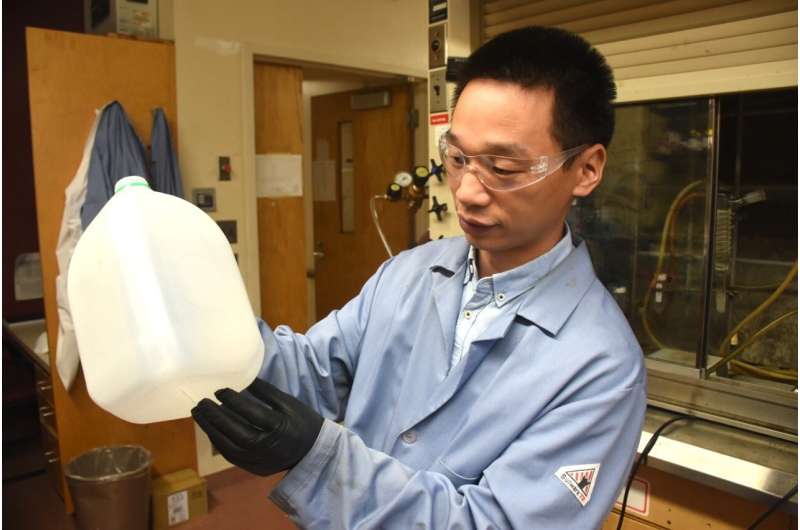

With the assistance of Zhen Xu and Eric Munyaneza, two Ph.D. chemistry college students in Liu’s lab, Liu constructed a small, oven-like reactor the place they may warmth polyethylene in a course of known as temperature-gradient thermolysis.

On the backside, the oven is at a excessive sufficient temperature to interrupt the polymer chains, and on the prime, the oven is cooled to a low sufficient temperature to cease any additional breakdown. After the thermolysis, they gathered the residue—just like cleansing soot from a chimney—and located that Liu’s hunch had been proper: It was composed of “short-chain polyethylene,” or extra exactly, waxes.

This was step one in growing a technique for upcycling plastics into cleaning soap, Liu mentioned. Upon including a couple of extra steps, together with saponification, the crew made the world’s first cleaning soap out of plastics. To proceed the method, the crew enlisted the assistance of consultants in computational modeling, financial evaluation, and extra.

A few of these consultants have been launched to the crew by way of connections with the Macromolecules Innovation Institute at Virginia Tech. Collectively, the group documented and refined the upcycling course of till it was able to be shared with the scientific neighborhood.

“Our analysis demonstrates a brand new route for plastic upcycling with out utilizing novel catalysts or complicated procedures. On this work, we’ve proven the potential of a tandem technique for plastic recycling,” mentioned Xu, lead writer on the paper. “This may enlighten folks to develop extra artistic designs of upcycling procedures sooner or later.”

Though polyethylene was the plastic that impressed this venture, the upcycling methodology also can work on one other sort of plastic often called polypropylene. These two supplies make up a lot of the plastic shoppers encounter each day by day, from product packaging to meals containers to materials. One of many thrilling options of Liu’s new upcycling methodology is that it may be used on each these plastics without delay, that means that it is not essential to separate the 2 from one another. This can be a main benefit over some recycling strategies used at the moment, which require cautious sorting of plastics to keep away from contamination. That sorting course of may be fairly troublesome, due to how comparable the 2 plastics are to one another.

One other advantage of the upcycling approach is that it has quite simple necessities: plastic and warmth. Though the later steps within the course of require some further components to transform the wax molecules into fatty acids and cleaning soap, the preliminary transformation of the plastic is an easy response. This contributes to the strategy’s cost-effectiveness in addition to its comparatively small environmental influence.

For upcycling to be efficient on a big scale, the ultimate product have to be useful sufficient to cowl the prices of the method and make it extra economically engaging than different recycling choices.

Though soaps might not initially seem to be a very costly commodity, they will truly be value double or triple the worth of plastics when put next by weight. At the moment, the common worth of cleaning soap and detergent quantities to about $3,550 per metric ton, and that of polyethylene is about $1,150 per metric ton. Moreover, the demand for soaps and associated merchandise is corresponding to the demand for plastics.

This analysis lays the groundwork for a brand new technique to cut back waste by channeling used plastics into the manufacturing of different helpful supplies, Liu mentioned. Over time, he hopes recycling amenities all over the world will start to implement this method. If that’s the case, then shoppers can count on to in the future have the chance to purchase revolutionary sustainable cleaning soap merchandise that additionally result in diminished plastic waste in landfills.

For that reason, turning plastics into soaps may be demonstrated to be economically viable, added Liu, who can also be an affiliated college member of the nanoscience program, a part of the Faculty of Science’s Academy of Built-in Science in addition to the Division of Supplies Science and Engineering within the Virginia Tech Faculty of Engineering.

“It must be realized that plastic air pollution is a worldwide problem slightly than an issue of some mainstream nations. In comparison with a complicated course of and sophisticated catalyst or reagent, a easy course of could also be extra accessible to many different nations worldwide,” Xu mentioned. “I hope this could be a good begin for the warfare combating plastic air pollution.”

Researchers from the Division of Chemical Engineering additionally have been a part of this venture and the ensuing analysis paper.

Extra info:

Zhen Xu et al, Chemical upcycling of polyethylene, polypropylene, and mixtures to high-value surfactants, Science (2023). DOI: 10.1126/science.adh0993. www.science.org/doi/10.1126/science.adh0993

Supplied by

Virginia Tech

Quotation:

Researchers develop methodology for upcycling plastic waste into cleaning soap (2023, August 10)

retrieved 11 August 2023

from https://phys.org/information/2023-08-method-upcycling-plastic-soap.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.

[ad_2]